Overview of the Dustac Sampler

The Dustac sampler (system model: ESA-703) is a normal type of automatic sampling device that conforms to the Methods of measuring dust concentration in flue gas (JIS Z 8808).

By entering the measurement conditions (measurement time, duct area, fluid density, etc.), and continuously measuring the data such as exhaust gas temperature, dynamic pressure, static pressure, atmospheric pressure, etc., it can calculate the theoretical isokinetic suction flow rate. It is equipped with suction control function that can automatically control the valve inside the device so that the theoretical value and the actual value always match by using a pulse signal to feed back the flow rate of suction actually sucked by the gas meter.

In addition, it is equipped with a variety of functions that can be used for moisture measurement such as automatic suction control, calculating moisture value (%) by inputting the moisture weighing value, and calculating appropriate nozzle diameter from the flow velocity value etc.

Product Component

① DUSTACK controller Model ESA-703C

|

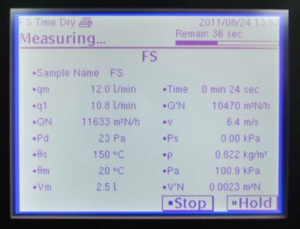

The DUSTACK controller consists of sensor amplifiers (dynamic pressure, total pressure, atmospheric pressure, exhaust gas temperature), a calculation display (touch panel) and a printer. It is used in combination with the automatic unit sampler. Each sensor amplifier is built into the DUSTACK controller, and transmits the measured values detected by the pitot tube and thermocouple to the calculation display unit. The calculation display section (touch panel) calculates and displays the necessary data for dust measurement from the input measurement conditions (measurement time, duct area, fluid density, etc.) and the signals transmitted from each sensor amplifier. In addition, the measurement results can be printed out on a printer and imported to a CF card.

|

|

|

Display sample |

② Automatic unit sampler

| Automatic unit samplers consist of dry gas meters, control valves, diaphragm pumps, etc. It automatically control the valve, which is used for automatic isokinetic suction, by signals from the DUSTACK controller. In addition, It can also be independently used as an automatic suction control device. There are two types, the gas meter built-in type and the separate type. |

|

③ Pre-treatment device

|

It is used to prevent corrosive gas and moisture from entering the suction pump and gas meter. There are three types of bottles: quadruple, triple, and double. |

|

④ Probe ( Composite sampling tube )

| It integrates a pitot tube, thermocouple, and dust collection tube. 1 to 3m in length, It can be extended with a connecting pipe (sold separately). |

|

⑤ Sampling cable set

|

A set of 2 rubber tubes for pitot tube, 1 rubber tube for suction, and 1 thermocouple compensating lead wire. |

|

⑥ Storage case

| Manufacture according to your request. |  |

Specification

1. DUSTACK controller

| Name | DUSTACK controller |

| Model | ESA-703C |

| Measuring object | Exhaust gas and gas |

| Measuring item | 5 items Details below |

| Input item | 23 items Details below |

| Calculating item | 1 item Details below |

| Output item | 5 items Details below |

| Measuring mode | Isokinetic suction mode、Constant suction mode、 Velocity・flow rate mode |

| Dimension・Weight | 323W×258H×198D ㎜ ・ Approx. 6kg |

| Power supply・consumption | AC85~265V ・ 30W |

| Accessories | Power cord 2m、Communication cable 1m、CF card 1 sheet |

■ Setting item/range

| Dynamic pressure | 0~1250 Pa Built-in sensor input |

| Total pressure | -20.00~20.00 kPa Built-in sensor input |

| Exhaust gas temperature | 0~1200 ゚C Thermoelectromotive force(K) |

| Atmospheric pressure | 90.0~107.0 kPa Built-in sensor input |

| Gas meter temperature | 0~50 ゚C resistance temperature detector(Pt100Ω) |

■ Recorder output items/range

| Dynamic pressure | 0~1250 Pa 0~1.25VDC |

| Exhaust gas temperature | 0~1200 ゚C 0~1.2VDC |

| Velocity | 0.0~100.0 m/s 0~1VDC |

■ Input items/range

| Input item | Symbol | Input range | Unit |

| Sample No. | S_No. | Alphanumeric character, '-' | |

| Suction time | TIME | 1~1440 | min |

| Suction volume | Vm | 10.0~10000.0 | L |

| Aggregate time | A_TIME | 1~1440 | min |

| Aggregate suction volume | A_Vm | 2.0~999.9 | L |

| Moisture value | Xw | 0.0~100.0 | % |

| Fluid density under standard conditions | ρ0 | 0.100~9.999 | kg/m3N |

| Carbon dioxide | CO2 | 0.00~100.00 | % |

| Oxygen | O2 | 0.00~100.00 | % |

| Carbon monoxide | CO | 0~10000 | ppm |

| Pitot tube coefficient | C | 0.100~2.000 | |

| Fluid temperature | θs | 0~1200 | ゚C |

| Gas meter temperature | θm | 0~50 | ゚C |

| Atmospheric pressure | Pa | 90.0~107.0 | kPa |

| Cross-sectional area | Area | 0.0001~99.9999 | m2 |

| Round duct diameter | PHID | 0.020~10.000 | m |

| Square duct x length | XD | 0.020~9.999 | m |

| Square duct Y length | YD | 0.020~9.999 | m |

| Nozzle diameter | d | 2.0~20.0 | φ |

| Constant suction volume | q1 | 1.0~50.0 | L/min |

| mass of absorbed water | ma | 0.0001~99.9999 | g |

| Purge time | PURGE | 2~60 | sec |

| Purge cycle time | CYCLE | 2~1440 | min |

■ Calculating item/range

| Input item | Symbol | Input range | Unit |

| Velocity | V | 0.0~100.0 | m/s |

| Static pressure | Ps | -20.00~20.00 | kPa |

| Moisture value | Xw | 0.0~100.0 | % |

| Fluid density | ρ | 0.100~9.999 | kg/m3 |

| Fluid density under standard conditions | ρ0 | 0.100~9.999 | kg/m3N |

| Wet flue gas flow rate | QN | 0~9999999 | m3N/h |

| Dry flue gas flow rate | Q´N | 0~9999999 | m3N/h |

| Isokinetic suction flow rate (theoretical value) | qm | 1.0~50.0 | L/min |

| Isokinetic suction flow rate (actual value) | q1 | 1.0~50.0 | L/min |

| Suction dry gas volume | V'N | 0 ~ 99.9999 | m3N |

| Conversion of sucked gas amount to the state inside the duct | Vs | 0 ~100.0000 | m3 |

2. Automatic unit sampler

Gas meter Built-in type ESA-703S

■ Control unit

| Gas meter | Dry type Measurement range 0.16 to 33.3 L/min Pointer 1 rotation 1 L Pulse transmission type (0.001 L/P) Minimum scale 5cc |

|||

| Control valve Manual valve |

Pulse motor driven ball valve Needle valve (course and bypass) |

|||

| Display panel | LED display 7-segment 8-digit | |||

| Vacuum gauge | For judging filter clogging, ventilation resistance, and pump capacity | |||

| Power supply/ consumption | AC100V・60W | |||

| Dimension/Weight | 350W×360H×255D ㎜・Approx.15kg | |||

| Accessories | Power cord 2m | |||

■ Suction part

| Pump | Diaphragm type 60L/min | |

| Power supply/ consumption | AC100V・600W Requires 2 kW or more at start-up | |

| Dimension/Weight | 350W×260H×255D ㎜・Approx. 17kg | |

| Accessories | Exhaust rubber pipe φ9×φ18 400mm (2 pieces) | |

Gas meter Separate type ESA-703SC

■ Control unit

| Control valve | Pulse motor driven ball valve | |

| Display panel | LED display 7-segment 8-digit | |

| Vacuum gauge | For judging filter clogging, ventilation resistance, and pump capacity | |

| Power supply/ consumption | AC100V・60W | |

| Dimension/Weight | 350W×360H×255D ㎜・Approx.15kg | |

| Accessories | Power cord 2m | |

■ Suction part

| Pump | Diaphragm type 60L/min |

| Manual valve | Needle valve (course and bypass) |

| Power supply/ consumption | AC100V・600W Requires 2 kW or more at start-up |

| Dimension/Weight | Approx.13kg |

| Accessories | Exhaust rubber pipe φ9×φ18 400mm (2 pieces) Power cord 2m |

■ Gas meter part

| Gas meter | Dry type Measurement range 0.16 to 33.3 L/min Pointer 1 rotation 1 L Pulse transmission type (0.001 L/P) Minimum scale 5cc |

|||

| Accessories | Temperature sensor, Pulse cable | |||